The various testing facilities available are :

Chemical Analysis

The Laboratory is equipped with a Baird Optical Emission Spectrometer to carry out chemical analysis on metals which includes

– Ferrous base (plain carbon and low alloy steels, cast irons, stainless steels and tool steels

– Aluminium base

– Copper base

– Nickel base

– Zinc base

– Titanium base

The Laboratory has a wide range of Certified Reference Materials to cover the entire range in each of these alloy systems to ensure reliability of test results.

Mechanical Tests

The Laboratory is well equipped to carry out tests to determine the mechanical properties of materials (rods, bars, plates, wires, etc.) The tests include

– Tensile tests (UTS, YS, 0.2% PS, % Elongation and % RA)

– Compression tests

– Bend Tests

– Customised load tests (pull out loads, push out load, breaking load, etc)

– Hardness Tests (Rockwell (HRA, HRB, HRC), Brinell, Vickers, microVickers)

Metallurgical Tests

The microstructure structure of materials has a direct bearing on the properties of a material. It also gives a measure of the adequacy of the treatment that the material is subjected to. Metallographic tests are also used to determine the cleanliness of steel.

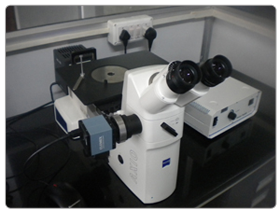

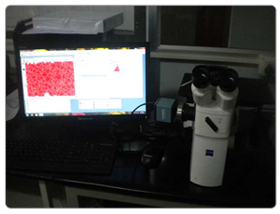

The Laboratory is equipped with a Zeiss inverted stage microscope along with a Clemex Vision Image Analysis system that is capable of analysing microstructures from 50x to 1000x magnifications.

The laboratory is equipped to carry out tests to determine

– Macrostructural examinations for rolled bars and grain flow tests for forgings

– Microstructural examinations (including evaluation of % of phases by image analysis and SMP methods)

– Inclusion Rating (as per ASTM E45)

– Decarburisation depth

– Case depth evaluation

– Coating thickness measurements

– Weld evaluations

– Grain size determination (by lineal intercept method, comparison methods and by automatic Image analysis methods)

All of the above tests are covered under the scope of NABL accreditation.

Corrosion Tests

The laboratory has facilities to carry out accelerated corrosion tests to determine life of the coated/painted articles as also to assess the corrosion rates of stainless steels.

Tests carried out include

– Intergranular corrosion (IGC) tests on austenitic/ferritic stainless steels

– Neutral Salt Spray Tests

– Pitting Corrosion

– Crevice Corrosion

Other Tests

– Estimation of coating thickness/coating weight on zinc and phosphate coated articles.

– Adhesion tests on plated / painted articles

– Tests for uniformity of coating on zinc and anodized articles.

– Area % porosity on thermal sprayed coatings.